Good morning members — and welcome to Thursday’s Tribune.

Six years ago, the former CEO of Sheffield Council John Mothersole welcomed “fast fashion” firm Pretty Little Thing to the city with open arms. The clothing company’s “distribution centre” on Shepcote Lane in Tinsley would, he said, bring thousands of new jobs to Sheffield and cement our status as an attractive base for logistics firms. Pretty Little Thing and its sister company Boohoo once claimed that at busy times of the year, 2,100 staff would work in the warehouse, but it’s a lot less than that now. A £150 million investment in the facility has brought in more automation, and people are now losing their jobs. Today, we go behind the scenes at Boohoo and ask whether rolling out the red carpet to “fast fashion” was a good idea.

Editor’s note: The fact that Boohoo is cutting staff in Sheffield has been reported elsewhere. But we wanted to go deeper and find out why so many redundancies were happening and what the implications were for our city. Over the last week I spent two days there, speaking to employees and finding out what was happening inside. If you think this kind of reporting is important and you want to ensure the survival of high quality journalism in Sheffield, please subscribe using the button above. It costs just £1.71 a week if you pay for a year upfront.

Your Tribune briefing

🚌 One of the new Sheffield Connect buses has been stolen just days after the service started. The vehicle was stolen from Sheffield Interchange overnight on Monday, 15 April, before being returned in the early hours of the morning. Debris from an apparent accident involving the bus was later found in the Killamarsh area. South Pennine Buses said that the incident had been "upsetting" but it was working "incredibly hard" to minimise any disruption.

🔵 Penistone and Stocksbridge MP Miriam Cates will not face any disciplinary action after she attended a gathering in parliament during the Covid lockdown in December 2020. An investigation found that while the gathering was in part a social event, her attendance had not caused significant damage to the reputation of the House of Commons. Mrs Cates said she “entirely regretted” what had happened and any embarrassment caused to Parliament.

🗳️ A Rotherham local election candidate who is standing under the name of “Phil Potholes” has been unmasked as former Yorkshire Party leader Chris Whitwood. He told the Local Democracy Reporting Service that he was inspired to stand as an independent in the Boston Castle ward after becoming fed up with the state of the local roads when his car was damaged by a pothole — adding that he came up with the name as a joke with friends.

Things to do

💀 At the Drama Studio on Friday, the award-winning writer of Upon the Stair and co-writer of Smile Club Adam Z. Robinson will present three gripping, gruesome tales from his Book of Darkness and Light, each with a different house at their heart. The thrilling show will combine chilling storytelling, an original score by Ben Styles, and fully integrated BSL to create an unforgettable theatrical experience. Tickets are £6-£13 and doors open at 8pm.

🎛️ To The Foundry (part of the Sheffield Students’ Union) on Saturday night come Daft Funk Live, the UK’s “most prestigious Daft Punk tribute act”. Since the robots split in 2021, Daft Funk Live are now one of your only chances to experience what it must have been like to see the band live. Their show includes authentic costumes, an amazing custom light show with over 1,500 LEDs, and a three-metre pyramid. Tickets are £16.50 and doors open at 7pm.

🥯 On Sunday, Sharrow Vale Market returns for the first time in 2024 with over 100 stalls selling a huge variety of locally sourced and homemade produce (12pm-4pm). As well as food there will also be crafts, plants, cosmetics, live music and singers, the Salvation Army Band and the Boogie Merchants mobile disco. Also taking place on Sunday (10am-4pm) is Pollen Market, the monthly celebration of all things botanical at Grey to Green in Castlegate.

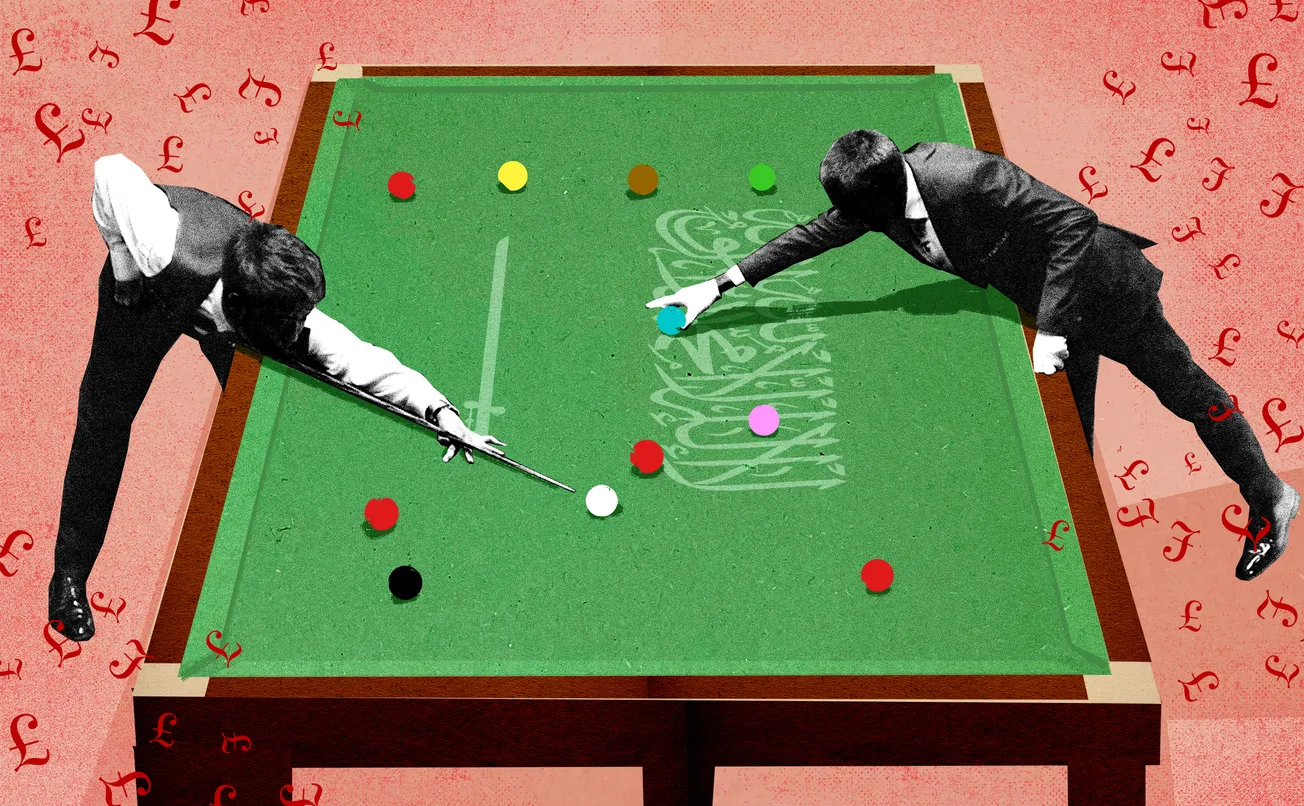

The rise of the machines: Is automation at Boohoo a sign of things to come?

Shepcote Lane, a snaking road that links the suburb of Greenland to the M1, is a part of Sheffield that many never see. South Yorkshire Police’s euphemistically named “custody suite” is located there, as well as a smattering of small businesses, a vehicle recovery firm, and a solicitors’ office. But what leaves the biggest impression is not a building, but a sound: the thunder of huge lorries making their way to and from the motorway.

Shepcote Lane is one of Sheffield’s biggest logistics hubs. There are several large warehouses in the area, but one dwarfs them all. The huge distribution centre for fashion company Boohoo and its sister company Pretty Little Thing is painted blue to blend in with the sky. It seems to go on forever, filling up the horizon. According to the company, at busy times such as the pre-Christmas period, this warehouse used to employ more than 2,100 people processing the distribution of clothes all over the UK — much needed jobs in a city still struggling to emerge from its industrial past.

When Pretty Little Thing arrived in Sheffield in April 2018, former Sheffield City Council chief executive John Mothersole described it as “a brilliant addition to the city’s jobs market”. But six years later, the warehouse has made a number of rounds of redundancies, while Boohoo has faced national criticism for its business practices and treatment of workers. Is this brilliance all it was cracked up to be?

Boohoo and Pretty Little Thing are some of the biggest players in the so-called “fast fashion” industry, a business model in which clothing is made so cheaply that in many cases they are worn once and then thrown away. As well as the environmental impact of cheaply made clothes (one study found that 84% of Boohoo’s clothes contained non-recycled plastic, while many unsold fast fashion items end up in landfill sites), and the often opaque supply chains that underpin them, in 2020, a Sunday Times investigation found staff working at a Boohoo supplier in Leicester were being paid just £3.50 an hour. The firm later admitted that conditions in the factory were “totally unacceptable and fall woefully short of any standards acceptable in any workplace”.

We’ve covered this warehouse before. In 2021, I spoke to staff about what it was like to work at the biggest logistics warehouse in Sheffield. Pretty Little Thing owner Umar Kamani had posted a photo of himself in the warehouse captioned: “This place makes me smile.” We explained why Kamani was smiling — £374m in sales for Pretty Little Thing in 2019 — but also explored why staff at the warehouse might not share his sunny disposition. Workers we spoke to painted a picture of an unpleasant working environment, of not being allowed to go home when they were ill, punishingly high performance targets and poor health and safety.

Things have changed a lot in the last three years — and not necessarily for the better. The last time we visited, the warehouse was operated by Clipper Logistics, a Leeds-based logistics firm which Pretty Little Thing partnered with when they took on the site in 2018. Now, while the Pretty Little Thing branding still displayed in the side of the building, the Clipper logo has vanished and online the warehouse is officially named Boohoo UK2, one of the firm’s two giant distribution centres in the UK (the other is in Burnley, Lancashire while a third in Daventry, Northamptonshire closed down earlier this year with the loss of 400 jobs).

They’ve changed inside, too. In 2021, the warehouse employed an army of ‘pickers’ — staff employed to collect items from around the 615,000 square foot or 14-acre warehouse and hand them to other employees to pack ready for distribution. However, following a £150 million investment in the facility, many of these picker jobs have been automated. “When the warehouse opened in 2018, everything was manual,” says one staff member. Now, paid staff have been replaced by a conveyor belt system. “It brings stuff to you rather than you having to go and get it,” they add.

On the one hand, this makes it “a lot easier” to pick, the staff member says, but it also means they need far fewer workers. The warehouse shed 300 jobs last September, with another 90 earlier this year. The man I’m speaking to works in the hygiene team, cleaning the vast warehouse ready for a new shift to start. This, he adds, is “better than picking” — but not by much. “[Boohoo]’s got a bad name, and it deserves it,” he says. “It’s just shit. You are just like a number; anonymous. They don’t care about you or do anything for you.”

Comments

How to comment:

If you are already a member,

click here to sign in

and leave a comment.

If you aren't a member,

sign up here

to be able to leave a comment.

To add your photo, click here to create a profile on Gravatar.